Rockets are all about power, and the type of fuel they burn plays a big role in how far they go. Traditional launchers often use solid or fully cryogenic engines. These engines, like GSLV Mk III (now known as LVM3), Chandrayaan-3’s, burn liquid hydrogen and liquid oxygen. They’re powerful but complex, and because hydrogen must be stored at −253°C, they require expensive insulation and precisely controlled systems.

Semi-cryogenic engines offer several advantages on that front. They also use supercooled liquid oxygen, but pair it with a refined form of kerosene called RP-1. This combination ticks off several boxes: high thrust, lower cost, easier handling, and potential for reusability.

While semi-cryogenic engines aren’t new, powering rockets like SpaceX’s Falcon 9 and Russia’s Soyuz, India’s homegrown version marks its own revolution.

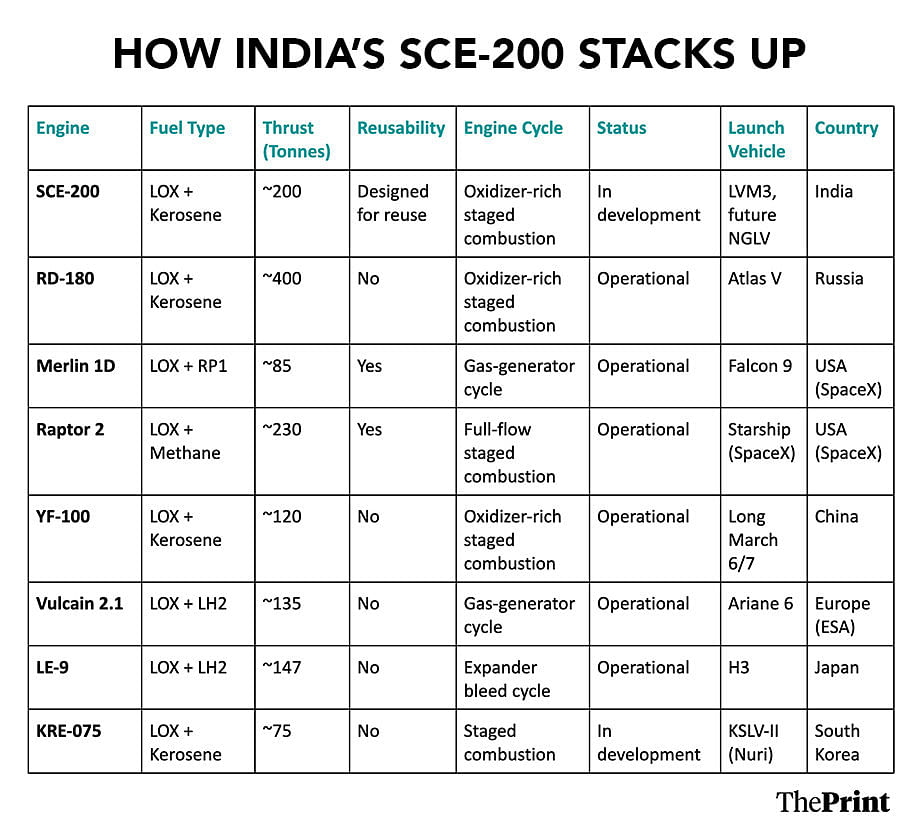

In March this year, ISRO a “major breakthrough” in the design and development of a semi-cryogenic engine at its Liquid Propulsion Systems Centre (LPSC). The engine, SCE-200, delivers 2,000 kN (200 tonnes) of thrust and is currently undergoing full-duration hot tests at the ISRO Propulsion Complex in Mahendragiri, following earlier collaborative trials in Russia.

Why the move? Because the advantages are too big to ignore. To begin with, semi-cryogenic engines provide greater thrust at liftoff, making them perfect for heavy payloads. The fuel is cheaper and easier to store than hydrogen, and their design is less complex, potentially improving reliability. They also support reusability, a key goal for future missions.

India isn’t just building a new engine. It’s building a new future—the SCE-200 is comparable to the best semi-cryogenic engines in the world.

Once certified, the SCE-200 will replace older stages on the LVM3 and eventually power India’s reusable launch vehicles and cargo missions to space stations or even the Moon. ISRO’s current heavy-lift vehicle, LVM3, is capable—but it’s due for an upgrade. The upcoming HLVM3 (Human-rated LVM3), which will carry Indian astronauts under the Gaganyaan mission, is expected to swap out its older liquid stages for a new semi-cryogenic core. This single move will increase lift capacity, improve safety margins, and enable longer-term goals like space station deployment, lunar bases, and Mars missions.

One of the most exciting things happening in Indian aerospace is how the government and startups are finally building together, better late than never.

Post-2020 reforms and the creation of IN-SPACe—an agency to promote private sector participation in space—opened up ISRO’s infrastructure to private companies. The result has been a propulsion renaissance of sorts.

Among the startups in this space, Hyderabad-based Skyroot Aerospace is developing semi-cryopowered variants of its Vikram rocket series, with an eye on modular, scalable launches. Chennai’s Agnikul Cosmosis pushing the boundaries with 3D-printed, single-piece semi-cryogenic engines like , dramatically cutting down manufacturing time and cost. And Bengaluru-based Bellatrix Aerospace is working on semi-cryogenic and green in-space propulsion systems, key to future satellite servicing and orbital transport.

Together, these fast, inventive, and globally ambitious startups are building India’s new propulsion economy.

From 2020 to 2023, the global space economy grew from $447 billion to over $, with the satellite launch market alone projected to reach $30 billion by 2030. India currently holds less than 2 per cent of global commercial launch revenue—but that figure is poised to change.

India is concentrating on improving the performance and cost-effectiveness of its launch vehicles with the forming of semi-cryogenic engines like the SCE-200. Compared to existing cryogenic upper stages, semi-cryogenic propulsion, which uses liquid oxygen and refined kerosene (RP-1 or comparable), provide better specific impulse and higher thrust-to-weight ratios.

The cost per kilogramme to Low Earth Orbit (LEO) for ISRO’s most potent operational launcher, the LVM3, is currently between $3,000 and $5,000. However, with effective mass production and reusable Merlin 1D semi-cryogenic engines, SpaceX’s Falcon 9 has lowered this cost to about $1,500 to $2,200 per kg. By switching to semi-cryogenic propulsion, ISRO may be able to cut launch costs by 30–40 per cent, to about $1,800–$3,200 per kilogramme, especially when combined with reusability features. This will increase India’s competitiveness against industry titans like SpaceX, Arianespace, and China’s CASC and bring its launch capabilities considerably closer to the international commercial norm.

Additionally, the thrust class of the SCE-200 (200 tonnes) puts it in line with the most recent booster engine development, enabling India to increase payload capacity for both orbital and interplanetary missions while reducing per-mission costs through economies of scale.

Moreover, ISRO’s PSLV and LVM3 missions already boast a launch success rate of over , and India has launched more than 430 foreign satellites to date. With semi-cryo integration and reusability, these numbers could scale drastically—positioning India as a low-cost, high-reliability launch hub for small satellite constellations, lunar payloads, and interplanetary missions.

This propulsion shift aligns with India’s ambition to claim a (10 per cent) share in the global space market by 2030, as projected by the Indian Space Association (ISpA). Semi-cryogenic technology is the engine behind that vision.

Semi-cryogenic propulsion isn’t just an incremental upgrade—it’s a transformative leap. These engines offer 30–40 per cent more thrust than conventional liquid engines, use RP-1 which is 10x denser than hydrogen (allowing compact design), and can cut launch costs by up to 20 per cent.

India’s entry into this league with indigenous development marks a critical inflection point. As a physicist, I see this as both a thermodynamic and economic optimisation—essential for scalable, reusable, and interplanetary missions. India is not catching up; it is leapfrogging into the propulsion technologies of tomorrow.

@NishantSahdev.

(Edited by Asavari Singh)